This toy was made for my son. I wanted to make an unusual gift. My search led to this project KAZKIN. This is a Rubber Band Gun.

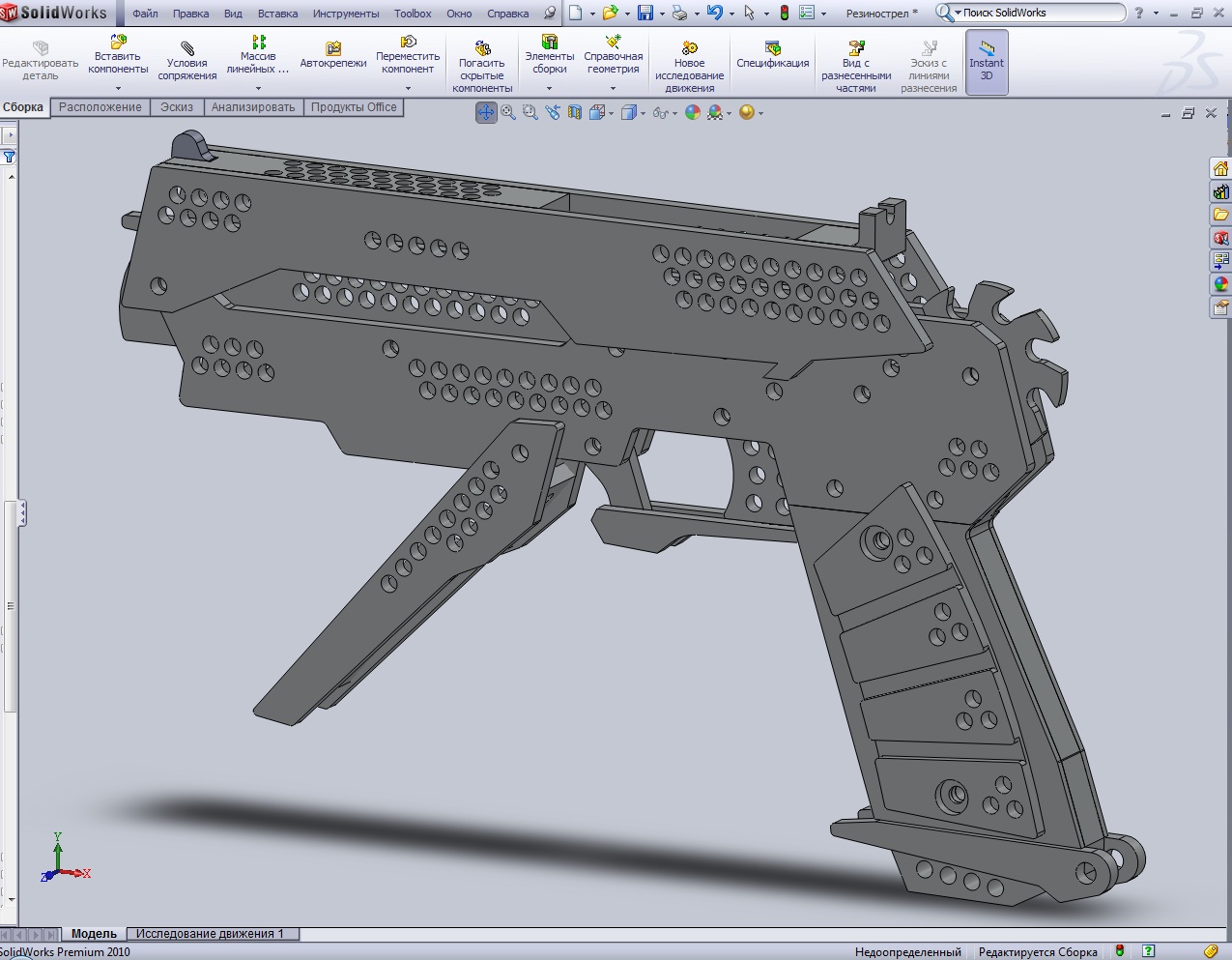

Of the variety of guns, I chose SilverWolf-SR.

But I could not find sketches and drawings. So I used the photos and videos from KAZKIN. After a few evenings I had the model of rubber band gun (SolidWorks).

I then used MasterCAM X4 and my mill. As a result I had the parts:

Schematic of the mechanism:

After assembling and debugging the toy was ready for my son!

You can download the parts of Rubber band gun. All parts are in the format of SolidWorks2010 and STL-files..

Comments

Keep on posting!

You are a champion. I had figured on something like that. Did you have to put some sort of stopper in to prevent the sear from resetting too far back after a shot?

I added a schematic of the mechanism. Is that enough? Any questions!

Ahh ok that answers some questions. I am personally printing not milling it so glue seems to be the best course of action. Thankyou very much for the reply

I did not use welding. Therefore needed extra holes for assembly.

regards

RSS feed for comments to this post